When it comes to precision and efficiency in crafting, construction, or even culinary tasks, having the right tools can make all the difference. Whether you’re a seasoned professional or a weekend DIY enthusiast, selecting the best cutters tailored to your specific needs can unlock a world of creativity and productivity. From versatile utility knives to specialized hobby blades, the market is teeming with options, each promising to enhance your cutting experience and deliver stunning results.

In this comprehensive guide, we delve into the top contenders in the realm of cutting tools, offering reviews and insights that will help you make an informed decision. We’ll explore the unique features, advantages, and potential drawbacks of various cutters, ensuring you find the perfect match for your projects. With the right knowledge at your disposal, you’ll be well-equipped to choose the best cutters that suit your style and elevate your craft.

Before moving on to our review of the best cutters, let’s first take a look at some related products available on Amazon:

Last update on 2025-12-14 / Affiliate links / Paid Links / Images from Amazon Product Advertising API

Overview of Cutters

Cutters are essential tools used across various industries, from construction and manufacturing to arts and crafts. These versatile instruments come in various shapes and sizes, designed to efficiently cut through different materials such as paper, fabric, plastic, and metal. Whether you are in a professional setting or engaging in a DIY project at home, having the right cutter can significantly enhance your precision and productivity.

There are several types of cutters available, each suited for specific tasks. Some of the most common types include utility knives, box cutters, rotary cutters, and scissors. Utility knives are popular for their retractable blades and ergonomic designs, making them safe and easy to use. Box cutters, on the other hand, are specifically designed to slice through cardboard and packaging materials with ease. Rotary cutters excel in fabric cutting, while scissors are a staple for everyday cutting needs.

When selecting the best cutters for your projects, it’s essential to consider the material you’ll be working with, as well as the level of precision required. High-quality cutters often feature replaceable blades, ensuring longevity and continued performance. Additionally, ergonomic designs with comfortable grips can help reduce fatigue during prolonged use, making them an ideal choice for both professionals and hobbyists alike.

In summary, cutters are indispensable tools that play a crucial role in various applications. Their diversity and functionality make them a go-to choice for anyone looking to accomplish cutting tasks efficiently. Investing in the best cutters ensures you are well-equipped for any project, whether at home, in the workshop, or on the job site.

5 Best Cutters

1. X-ACTO #1 Knife

The X-ACTO #1 Knife is a classic choice among crafters and professionals alike. Its precision ground blade makes it ideal for intricate cutting tasks, whether you’re working on art projects, models, or detailed crafts. The lightweight handle and ergonomic design provide comfort during prolonged use, reducing hand fatigue while allowing for dexterous movements.

In addition to its sharpness, the X-ACTO #1 features a simple blade replacement mechanism, ensuring that you can keep your cutting tool functioning at its best. The knife’s versatility across a range of materials—from paper to thin plastic—makes it a staple in any toolkit. Its compact size makes it easy to store or carry, which is perfect for artists and hobbyists on the go.

2. OLFA 18mm Rotary Cutter

The OLFA 18mm Rotary Cutter is a must-have for anyone serious about quilting, sewing, or crafting. With a blade that effortlessly slices through multiple layers of fabric, it saves time and enhances precision compared to traditional scissors. The ergonomic handle is designed for comfort, allowing prolonged use without discomfort, which is crucial for larger projects.

What sets this rotary cutter apart is its safety features; the blade retracts automatically when not in use, significantly reducing the risk of accidents. Its lightweight design and smooth rolling action make it easy to maneuver, providing clean cuts every time. This cutter is suitable for both beginners and seasoned crafters who require a reliable cutting tool.

3. Fiskars 8 Inch Softgrip Scissors

Fiskars 8 Inch Softgrip Scissors are engineered for versatility, making them perfect for a variety of cutting tasks, from crafts to office work. The stainless steel blades are super sharp and designed to cut through paper, fabric, and more with ease. The softgrip handle provides added comfort, ensuring a secure grip while you work for extended periods without straining your hands.

These scissors stand out due to their durable construction and corrosion-resistant properties, ensuring they maintain their cutting edge over time. The slightly larger size is ideal for cutting through tougher materials, while the iconic orange handles make them easy to spot in any toolkit. Overall, these Fiskars scissors are a reliable choice that balances functionality and comfort seamlessly.

4. Nuovoware Corner Cutter

The Nuovoware Corner Cutter is an exceptional tool designed for anyone looking to create beautifully rounded corners on various materials. This compact cutter can handle paper, cardstock, and photos, making it an essential tool for scrapbooking, crafting, and project presentations. Its five interchangeable heads allow for different corner radii, offering customization to suit your project needs.

Using the Nuovoware Corner Cutter is easy, with a simple squeeze mechanism that provides precise cuts every time. Its sturdy build ensures durability, so you won’t have to worry about wear and tear, even with regular use. For those who strive for polished and professional-looking projects, this corner cutter is an excellent investment that greatly enhances the aesthetics of your work.

5. Stanley 10-099 6-Inch Classic Utility Knife

The Stanley 10-099 Classic Utility Knife is a heavyweight champion in the world of cutting tools. Known for its durability and versatility, this utility knife is perfect for a range of tasks from home improvement to crafting. Its retractable blade mechanism allows for quick and safe storage, and the knife’s robust design can handle tougher materials, making it ideal for heavy-duty jobs.

Moreover, the ergonomic handle provides a comfortable grip that minimizes hand strain, even with extended use. The ability to easily change blades means you can keep your projects moving without interruption. Whether you’re tackling a DIY home project or need a reliable cutter in your toolbox, the Stanley 10-099 is a dependable choice that meets high standards of quality and performance.

Why Do People Need to Buy Cutters?

Cutters are essential tools that serve a wide range of purposes across various industries and everyday tasks. From crafting and home improvement projects to professional applications in construction and manufacturing, the demand for efficient cutting tools is ever-present. The right cutter not only enhances productivity but also ensures precision, safety, and ease of use, making it a fundamental item in any toolkit.

One primary reason people invest in cutters is the versatility they offer. Different types of cutters are designed for specific materials and tasks, whether you’re working with paper, fabric, plastic, or even metal. For instance, utility knives are perfect for general cutting purposes, while rotary cutters provide clean cuts for quilting and sewing projects. This versatility makes them indispensable for hobbyists, DIY enthusiasts, and professionals alike, allowing users to tackle a variety of tasks with just one tool.

Moreover, using the best cutters can significantly improve the quality of work produced. A well-made cutter can ensure cleaner edges and more precise measurements, which is crucial for projects that require attention to detail. Whether you’re a designer looking to create perfect patterns or a contractor needing reliable tools for construction, the performance of a cutting tool can directly impact the outcome of a project. Thus, investing in high-quality cutters can make a substantial difference in both efficiency and results.

Lastly, safety is a critical factor when it comes to cutting tools. Many modern cutters come equipped with safety features designed to minimize the risk of accidents and injuries. Ergonomic handles, retractable blades, and safety guards allow users to handle the tools with confidence. As people prioritize safety in their workspaces and workshops, choosing the right cutter becomes essential not just for effectiveness but also for ensuring a secure working environment. Understanding these aspects emphasizes why investing in quality cutters is a wise decision for anyone engaged in cutting tasks.

Types of Cutters

Cutters come in various forms, each designed for specific tasks and materials. Some of the most common types include utility knives, box cutters, rotary cutters, and scissors. Utility knives are versatile tools often used in construction and renovation projects, allowing for precise cuts in cardboard, rope, and even drywall. Box cutters, with their retractable blades, are ideal for safely opening packages and cutting through packaging materials.

Rotary cutters, often popular among quilters and crafters, offer a circular blade that allows for smooth, clean cuts through multiple layers of fabric. Scissors, while more generalized, can be categorized into different types such as sewing scissors, kitchen shears, and craft scissors, catering to a broad range of cutting needs. Understanding these distinctions is crucial when selecting the right cutter for your specific project.

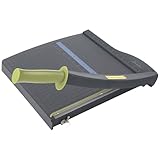

In addition to these traditional options, there are also specialized cutters like paper trimmers and wire cutters. Paper trimmers are essential for clean, straight cuts in crafting and office environments, whereas wire cutters are designed for electrical work and crafting that involves thin metal materials. By recognizing the types of cutters available, you can make informed decisions that enhance efficiency and effectiveness in your tasks.

Materials and Blades

The choice of materials and blades for cutters plays a significant role in their performance and longevity. High-carbon stainless steel is a common material for blades as it offers a good balance between sharpness and corrosion resistance. This type of steel retains its edge well and can withstand heavy use, making it suitable for professional applications as well as home use.

Additionally, ceramic blades are gaining popularity due to their exceptional sharpness and resistance to wear and tear. They can maintain their edge longer than steel blades, but they are more brittle, making them less suitable for heavy-duty tasks. When selecting a cutter, consider the type of material you will be cutting and how frequently you will use the tool, as this can influence the choice of blade and overall cutter durability.

Another important aspect to consider is the blade design and shape. Various shapes, such as straight, serrated, or wavy edges, are better suited for different cutting tasks. For example, serrated blades are excellent for cutting through tougher materials like rope and fabric, while straight blades provide precision for delicate tasks. Ensuring that your cutter’s blade matches your cutting needs is essential for achieving optimal results.

Ergonomics and Design

The ergonomics of a cutter significantly influence user comfort and efficiency during prolonged use. A well-designed grip that fits comfortably in the hand can prevent fatigue and potential injuries, enhancing productivity. Many modern cutters feature rubberized or contoured handles that provide a secure grip, allowing for better control and reducing the risk of slipping during use.

In addition to grip design, the weight and balance of a cutter play crucial roles in user experience. A cutter that is too heavy can lead to discomfort, while one that is too light may compromise the cutting force needed for certain materials. Finding a balance between the two can help users maintain accuracy and comfort throughout their cutting tasks.

Another aspect to consider in the design of cutters is safety features. Many models come equipped with safety locks, retractable blades, or sheaths that protect users when the cutter is not in use. These features not only enhance safety but also increase the longevity of the cutter by preventing accidental damage to the blade when not actively being used. Prioritizing ergonomics and safety in your selection will result in a more satisfying cutting experience.

Maintenance and Care for Cutters

Proper maintenance and care for cutters are essential to ensure their longevity and optimal performance. Regularly cleaning the blades, especially after use with sticky or messy materials, prevents build-up that can dull the cutting edge. Depending on the type of cutter, you may be able to carefully remove the blade for thorough cleaning, or simply wipe it down with a suitable cloth and cleaner.

Additionally, sharpening blades is a crucial part of maintenance that many users overlook. Dull blades require more effort to use and can lead to imprecise cuts, making it essential to periodically sharpen your cutters. Investing in a quality blade sharpener or utilizing professional sharpening services can extend the life of your cutting tools, resulting in better performance and less frustration.

Storage also plays a significant role in preserving the quality of your cutters. Keeping them in a dedicated, dry place protects against moisture and prevents accidental damage. Consider using blade guards or sheaths to shield the blades from accidental dulling or injuries when not in use. By implementing proper care and maintenance routines, you can maximize the efficiency and lifespan of your cutters, ensuring they remain reliable tools in your workspace.

Buying Guide: Best Cutters

When it comes to achieving precision and efficiency in cutting tasks, choosing the right cutter is essential. Whether for home crafting, professional work, or industrial use, the variety of cutters available on the market can be overwhelming. This buying guide is designed to help you navigate through the options and consider the most important factors to find the best cutters that meet your needs.

1. Type of Cutter

The first factor to consider when purchasing a cutter is the type you need for your specific task. There are various types of cutters available, including rotary cutters, utility knives, scissors, and specialty cutters for materials like paper, fabric, or metal. Each type has its strengths and is suited for different applications. For instance, rotary cutters are favored in quilting and fabric cutting due to their ability to deliver clean, straight cuts, while utility knives are versatile tools that can be used for a range of cutting tasks.

When selecting the type of cutter, consider the materials you will primarily be working with. If you frequently cut through heavy materials, a heavy-duty cutter may be the best option. On the other hand, lightweight cutters are ideal for delicate tasks such as detailed crafting. Understanding the specific cutting requirements of your projects will guide you toward the cutter that best suits your needs.

2. Blade Material

The material of the blade is a critical element that significantly impacts a cutter’s performance and durability. Blades can be made from various materials, such as stainless steel, carbon steel, or specialty alloys, each offering different levels of sharpness, rust resistance, and longevity. Stainless steel blades are known for their resistance to corrosion, making them a reliable choice for use in humid or wet conditions.

Additionally, the hardness of the blade’s material can affect its cutting efficiency. Harder blades tend to retain their sharpness longer, which is beneficial for continuous use, while softer blades are easier to sharpen but may dull more quickly. Assessing your cutting frequency and the materials you will encounter can help determine the most appropriate blade material when searching for the best cutters for your applications.

3. Handle Design

The design and ergonomics of the cutter’s handle are essential for comfort and control during use. A well-designed handle can reduce fatigue and improve your precision while cutting. Look for features such as soft grips, contoured shapes, and non-slip materials to ensure a comfortable fit in your hand, especially if you plan on using the cutter for extended periods.

In addition to comfort, handle design affects the overall safety of the cutter. Some models incorporate safety features, like retractable blades or locking mechanisms, to help prevent accidental cuts when not in use. Ensuring that the handle provides a secure grip can help maintain control during cutting tasks, reducing the risk of injuries.

4. Cutting Capacity

Every cutter comes with different cutting capacities, which refer to the thickness or type of material it can handle effectively. For instance, paper cutters have various cutting limits based on their design, while fabric cutters might be engineered to handle multiple layers of fabric at once. Assessing the thickness and density of the materials you need to cut will guide you toward the right cutter that can tackle your projects efficiently.

Some cutters also come with adjustable cutting depths or widths, allowing for greater versatility. This can be especially useful for individuals who work with various materials or engage in multiple projects. Identifying your cutting requirements will help ensure that you invest in a cutter with an appropriate cutting capacity, maximizing your efficiency while minimizing the risk of damaging materials.

5. Portability and Storage

Consideration of how often you’ll need to transport your cutter or store it safely is another critical factor. If you plan to use the cutter in multiple locations, it’s best to choose a lightweight and portable option that is easy to carry around. Some cutters feature compact designs that conveniently fit into toolboxes or work bags, making them practical for on-the-go use.

Storage also plays a vital role in maintaining the longevity of your cutter. Look for models that come with protective sheaths or cases to safeguard the blade when not in use. Proper storage helps prevent accidental cuts and ensures that the blade remains sharp and intact. Taking into account both portability and storage options will contribute to a more efficient workflow, enhancing your crafting or work experience.

6. Price and Warranty

The final factor to consider is the price of the cutter and the warranty it comes with. Cutters can vary greatly in price based on their type, brand, and features. It’s essential to establish a budget that allows you to invest in a quality cutter without overspending. While it may be tempting to choose the cheapest option, consider the value and longevity of the cutter first, as a more expensive, durable cutter could save you money in the long run.

Additionally, many reputable brands offer warranties or satisfaction guarantees, which add an extra layer of security to your purchase. A warranty indicates that the manufacturer stands behind their product’s quality. Reviewing the warranty terms can provide peace of mind, assuring you that you’ll be covered in case of defects or issues with the cutter. Balancing price and warranty options can help you find the best cutters that provide both quality and assurance in your purchase.

FAQ

What types of cutters are available in the market?

There are several types of cutters available, each designed for specific tasks. Common types include utility knives, rotary cutters, and box cutters. Utility knives are versatile tools, ideal for various cutting jobs, from opening packages to crafting projects. Rotary cutters, often used in quilting or sewing, feature a circular blade that rolls across the material, making them perfect for cutting multiple layers of fabric. Box cutters, typically used in industrial or shipping settings, have retractable blades designed for safety and efficiency when cutting cardboard.

In addition to these, specialized cutters exist for specific tasks. These include paper cutters, which feature a straight edge and a guillotine-style blade for clean cuts, and wire cutters for trimming various types of wire. Electric cutters are also available for heavy-duty tasks, providing a faster cutting process for larger or tougher materials. When selecting a cutter, it’s important to consider the specific needs of your project and the material you’ll be working with.

How do I choose the right cutter for my needs?

Choosing the right cutter involves assessing the material you will be cutting and the precision required for the task. For simple cutting tasks, a utility knife or box cutter is often sufficient. However, for more precise cuts, especially in fabric or when working on intricate designs, a rotary cutter or a specialized paper cutter may be preferable. It’s also essential to consider blade quality and the handle’s ergonomics, as comfort during extended use can significantly impact your workflow.

Additionally, think about safety features and ease of blade replacement. Some cutters come with retractable or safety blades that reduce the risk of accidental cuts, while others may offer ergonomic grips to prevent slippage. If you anticipate using the cutter frequently, investing in a higher-quality option may enhance durability and performance. Always read reviews and consider user feedback to make an informed decision about which cutter best fits your needs.

What features should I look for in a quality cutter?

When evaluating a cutter’s quality, blade material and sharpness are critical factors. Stainless steel blades are often preferred due to their corrosion resistance and longevity. A sharp blade not only makes cleaner cuts but also requires less force, reducing the likelihood of accidents. Many quality cutters also feature replaceable blades, allowing users to maintain optimal performance over time. Look for cutters with blades that can be easily swapped out, as this will save you time and frustration.

Another important feature to consider is the handle design. A well-designed ergonomic handle provides comfort during prolonged use and helps prevent hand fatigue. Additionally, some cutters come with safety mechanisms, such as auto-retracting blades or finger guards, which can enhance safety. Other features that may add value include built-in storage for spare blades and cutting mats or guides to ensure straight cuts. Always check user reviews and ratings to gauge the quality and effectiveness of the cutter before making a purchase.

Are electric cutters worth the investment?

Electric cutters can be a worthwhile investment if you regularly engage in cutting tasks that require speed and efficiency. These tools can significantly reduce the time and effort needed for large projects since they often cut through materials with less physical exertion compared to manual options. They are particularly beneficial in settings that involve repetitive cutting tasks, such as in crafting, upholstery, or packaging industries. The power and precision of electric cutters can lead to cleaner cuts and a more polished final product.

However, it’s important to consider the initial cost and maintenance associated with electric cutters. While they can be more expensive upfront compared to manual cutters, their durability and efficiency might make them cost-effective in the long run. Additionally, ensure that you are comfortable with using electric tools, as they may require specific safety precautions. Assess your personal or business needs carefully—if your cutting tasks are sporadic, a manual cutter may still be the most convenient option for you.

How can I maintain my cutter for longevity?

Regular maintenance is essential for ensuring the longevity of your cutter and the quality of its performance. For manual cutters, keep the blades sharp to ensure clean cuts. Dull blades can lead to increased force and potential accidents. If your cutter has replaceable blades, change them regularly based on usage to maintain optimal cutting performance. After each use, clean the blade and the handle area to remove any debris or residue, which can affect functionality and safety.

For electric cutters, follow the manufacturer’s instructions for maintenance and battery care. Regularly check for any buildup of dust or debris in the cutting mechanism and ensure the blades are sharp. If your electric cutter is rechargeable, be mindful of charging practices to avoid overall battery deterioration. Proper storage is also critical; keep your cutter in a designated place where it won’t be damaged or misplaced. By following these maintenance tips, you can extend the life of your cutter and enhance its performance with each use.

What safety precautions should I follow when using a cutter?

Safety is paramount when using any cutting tool, and there are several precautions you should take. Always use the cutter for its intended purpose to avoid accidents. Ensure the material you are cutting is secured and stable, preventing it from shifting during the cutting process. If you’re using a utility knife, for example, always cut away from your body to minimize the risk of injury. Wearing appropriate personal protective equipment, such as gloves or safety glasses, can also provide added protection against potential accidents.

Additionally, it’s important to keep your cutting area organized and free of obstacles. Clutter can lead to accidents and hinder your movement. If you’re working with power tools, make sure to read the user manual carefully to understand any specific safety requirements. Regularly inspect your cutter for any signs of damage and avoid using it if you notice any issues that could impact its performance or safety. Practicing caution and being aware of your surroundings will help ensure a safe cutting experience.

Final Verdict

In conclusion, selecting the best cutters is paramount for achieving precision and efficiency in your projects, whether for crafting, construction, or culinary purposes. With a diverse range of options available, it is essential to consider the specific features that cater to your needs, such as blade material, handle design, and safety mechanisms. By making an informed decision based on our comprehensive reviews and buying guide, you can ensure that your investment enhances your productivity and overall experience.

Ultimately, the right cutter can make a significant difference in your tasks, elevating your work quality and providing the reliability you need. Don’t overlook the importance of choosing the best cutters that align with your requirements. Take the time to explore the various models and brands highlighted in our guide, and let your choice reflect the high standards of both performance and durability that you deserve.